Gentle, powerful, energy-saving

Digital pressure control ensures rapid and gentle vacuum drying. Its speed-controlled vacuum pump (accessory) saves around 70% energy.

Intuitive Operation

Touch, turn & go! Easy and intuitive operation with the unique Memmert ControlCOCKPIT and software AtmoCONTROL. more

High-quality Stainless steel

Beautiful and functional. Memmert stainless steel is scratch resistant, hygienic, robust and ever-lasting. more

Unlimited communication

Memmert appliances are equipped with state of the art interfaces for programming and communication. more

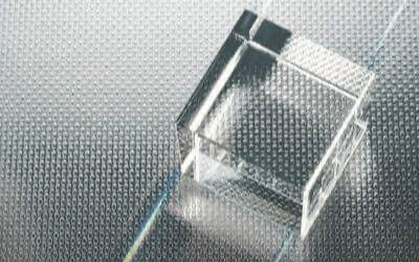

Reliable, comfortable and energy-efficient - that’s how vacuum drying works today.

Separately adjustable and directly heated thermoshelves ensure precise temperature control and, thanks to the digital pressure control, the chamber load is not only dried at high speed but also extremely gently in our powerful and robust vacuum drying oven.

Together with the speed-controlled vacuum pump, the vacuum oven VO forms an unbeatably energy-efficient duo. The pump is perfectly tidied away in the matching base cabinet.

5 to 1100 mbar

Vacuum control range

3 model sizes

29 to 101 litres volume

A Memmert vacuum drying oven offers unique advantages

- User-friendly, intuitive operating concept

- Nearly exclusive use of high-quality, rust-resistant and easy to clean stainless steel for interior and exterior housing

- Precise and homogenous temperature control thanks to a product-specific heating concept

- Anti-splinter; VDE-tested door construction for all models

- Temperature range extendable to up to 220 °C with the m360 option

- Pump control: Optimised rinsing of the pump membrane as well as signal output for switching the pump ON/OFF according to requirements

- Optional: Pump base cabinet and energy-efficient vacuum pump

- A wide range of options for programming and documentation using interfaces, integrated data loggers and the AtmoCONTROL software

- 3 years guarantee worldwide

Significantly reduced heating-up and processing times in the vacuum drying oven

When vacuum drying large quantities of powder or granulate, the vacuum cycles, which Memmert is the only manufacturer worldwide to offer, come into play perfectly: Two vacuum values can be set, between which the pressure is oscillated under controlled conditions. This way, a large amount of dry air is admitted within a short time, which absorbs humidity and is immediately extracted by the vacuum pump.

Uniquely precise: The Memmert VO direct heating system

Multi-Level-Heating & Sensing: intelligent direct heating via individually placeable thermoshelves with separate sensors guarantees short heating and process times in the Memmert vacuum drying oven. The control circuits react precisely to different loads or humidity and maintain a constant set temperature during vacuum drying. Thanks to the direct contact between the heating and the load, practically no heat loss occurs. Each thermoshelf can be individually calibrated.

Climate-friendly accessories: Vacuum pump saves around 70 % energy

The spectrum for vacuum drying in a Memmert vacuum oven VO ranges from foodstuffs to cosmetics, granulate, watches, books, printed circuit boards, to electronic components or injection moulds.

Due to the low final vacuum of the speed-controlled, chemical-resistant vacuum pump of up to 2 mbar - the aforementioned is possible.

The demand-oriented pump control ensures a significantly longer service life for the membranes. The energy-saving potential is particularly impressive compared to an uncontrolled vacuum pump. With representative measurements in ramp operation, energy consumption was around 70 % lower, and even better values were achieved with a constant vacuum value.

The speed-controlled Memmert vacuum pump is automatically detected by every vacuum drying oven VO. In the event that another vacuum pump or a central vacuum supply is connected, the vacuum is controlled via solenoid valves.

Products related to this item

Cooled vacuum oven m360 VOcool

Innovative vacuum drying for temperature-sensitive materials

Universal Oven U

Precise drying, heating, ageing, burn-in and hardening in research, science, industry and quality assurance.