The universally applicable lab oven U is Memmert’s classic appliance for temperature control in science, research and material tests in industry. The technologically perfected masterpiece made of high-quality, hygienic, easy-to-clean stainless steel leaves nothing to be desired in terms of ventilation and control technology, overtemperature protection and precisely tuned heating technology.

On this page, you can find all the essential technical data on the universal Memmert lab oven. Our customer relations team will be pleased to help if you want further information. If you should require a customised special solution, please contact our technical specialists at sales@memmert.com.

Temperature

| Working temperature range | at least 5 (UN/UNplus/UNm/UNmplus) or 10 (UF/UFplus/UFm/UFmplus) above ambient temperature to +300 °C |

|---|---|

| Setting accuracy temperature | up to 99.9 °C: 0.1 / from 100 °C: 0.5 |

| Setting temperature range | +20 to +300°C |

| Temperature sensor | 1 Pt100 sensor DIN class A in 4-wire-circuit |

Control technology

| ControlCOCKPIT | SingleDISPLAY. Adaptive multifunctional digital PID-microprocessor controller with high-definition TFT-colour display |

|---|---|

| Timer | Digital backwards counter with target time setting, adjustable from 1 minute to 99 days |

| Function SetpointWAIT | the process time does not start until the set temperature is reached |

| Calibration | three freely selectable temperature values |

| adjustable parameters | temperature (Celsius or Fahrenheit), air flap position, programme time, time zones, summertime/wintertime |

Ventilation

| Convection | natural convection |

|---|---|

| Fresh air | Admixture of pre-heated fresh air by electronically adjustable air flap |

| Vent | vent connection with restrictor flap |

Communication

| Documentation | programme stored in case of power failure |

|---|---|

| Programming | AtmoCONTROL software for reading out, managing and organising the data logger via Ethernet interface (temporary trial version can be downloaded). USB stick with AtmoCONTROL software available as accessory (on demand). |

Safety

| Temperature control | adjustable electronic overtemperature monitor and mechanical temperature limiter TB, protection class 1 according to DIN 12880 to switch off the heating approx. 20°C above nominal temperature |

|---|---|

| Autodiagnostic system | for fault analysis |

Standard equipment

| Works calibration certificate | Calibration at +160°C |

|---|---|

| Door | fully insulated stainless steel door with 2-point locking (compression door lock) |

| Internals | 2 stainless steel grid(s), electropolished |

Stainless steel interior

| Interior | easy-to-clean interior,made of stainless steel, reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides |

|---|---|

| Volume | 161 l |

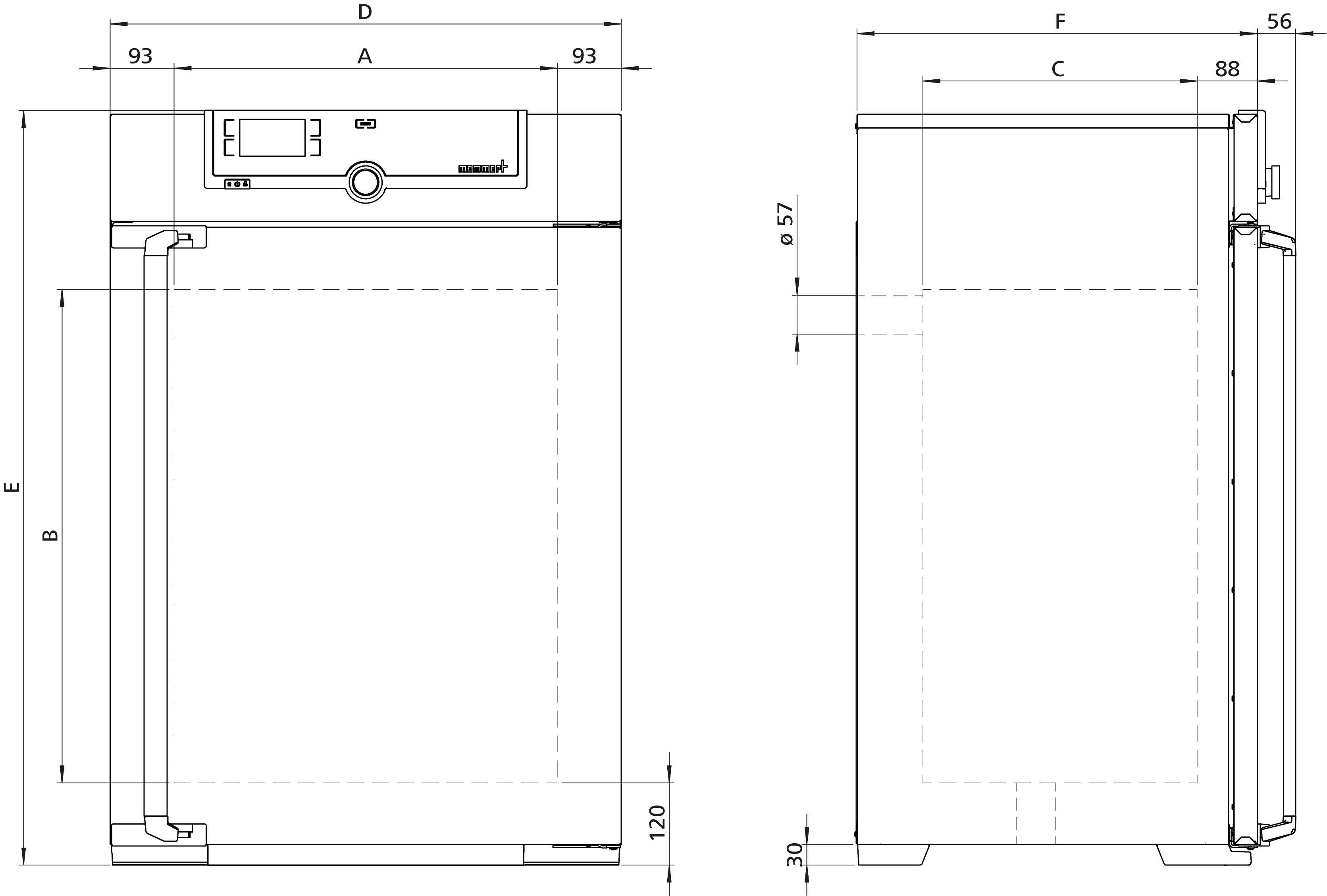

| Dimensions | w(A) x h(B) x d(C): 560 x 720 x 400 mm |

| Max. number of internals | 8 |

| Max. loading of chamber | 210 kg |

| Max. loading per internal | 20 kg |

Textured stainless steel casing

| Dimensions | w(D) x h(E) x d(F): 745 x 1104 x 584 mm (d +56mm door handle) |

|---|---|

| Housing | rear zinc-plated steel |

Electrical data

| Voltage Electrical load | 230 V, 50/60 Hz approx. 3200 W |

|---|---|

| Voltage Electrical load | 115 V, 50/60 Hz approx. 1800 W |

Ambient conditions

| Set Up | The distance between the wall and the rear of the appliance must be at least 15 cm. The clearance from the ceiling must not be less than 20 cm and the side clearance from walls or nearby appliances must not be less than 5 cm. |

|---|---|

| Altitude of installation | max. 2,000 m above sea level |

| Ambient temperature | +5 °C to +40 °C |

| Humidity rh | max. 80 %, non-condensing |

| Overvoltage category | II |

| Pollution degree | 2 |

Packing/shipping data

| Transport information | The appliances must be transported upright |

|---|---|

| Customs tariff number | 8419 8998 |

| Country of origin | Federal Republic of Germany |

| WEEE-Reg.-No. | DE 66812464 |

| Dimensions approx incl. carton | w x h x d: 830 x 1300 x 800 mm |

| Net weight | approx. 96 kg |

| Gross weight carton | approx. 122 kg |

Standard units are safety-approved and bear the test marks